Immersion Heater

[ + ] Hover to see full image

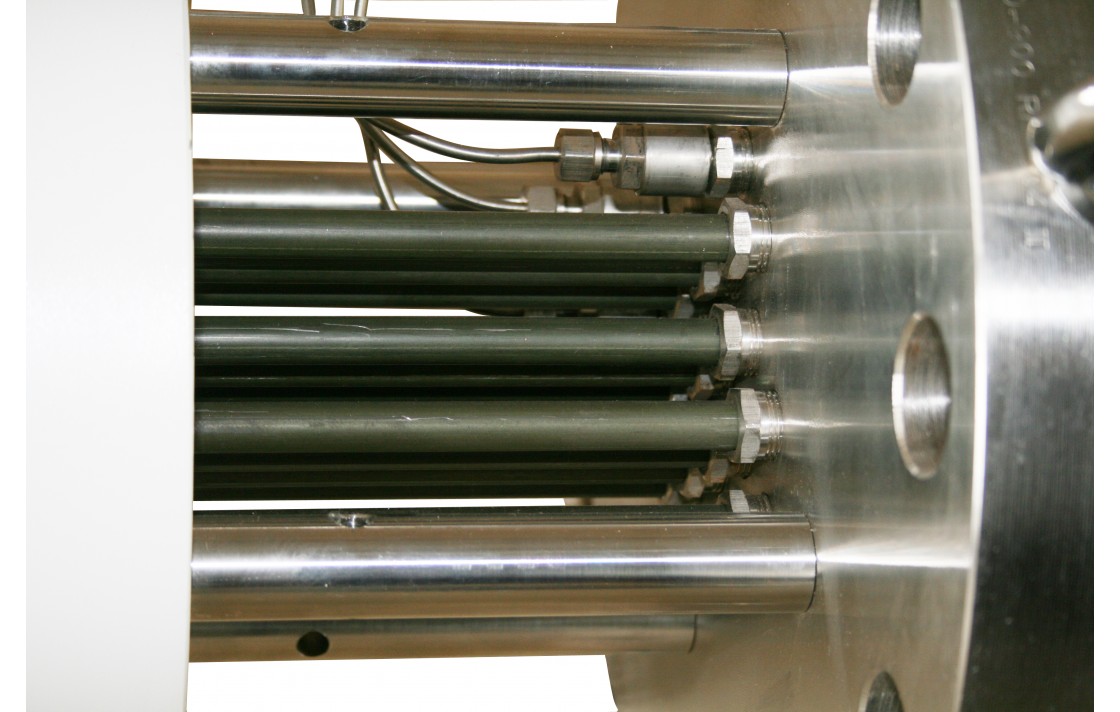

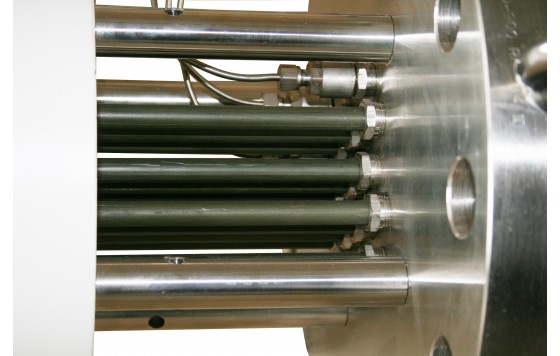

- Picture 1: Immersion Heater 285kW

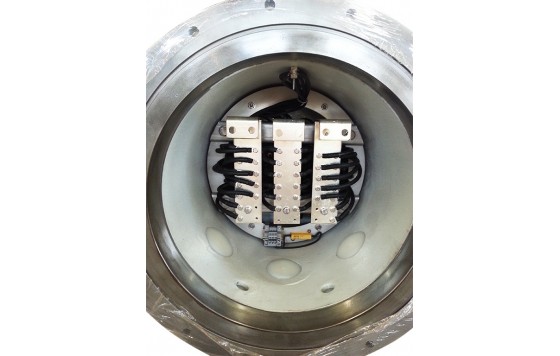

- Picture 2: Immersion Heater Exd Terminal Box

- Picture 3: Immersion Heater Exe Terminal Box

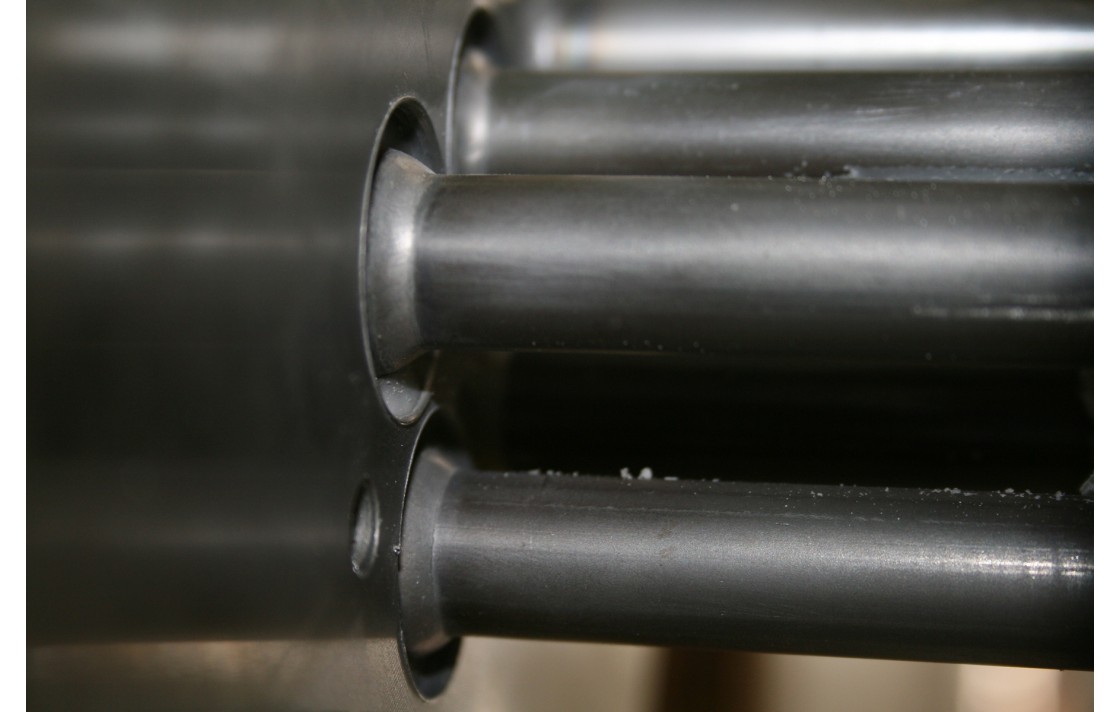

- Picture 4: Immersion Heater Bite Coupling

- Picture 5: Immersion Heater Direct Welding

Overview

Use in tank heating, usually for stagnant liquid to heat up and maintain at certain desire temperature. Multiple immersion heaters are used for a bigger tank dimension where heat distribution can be spread more widely. Temperature control by means of ON/OFF thermostat or contactor is adequate where precise control is not required.

Typical Applications:

- Closed Drain Drum

- Open Drain Drum

- Separators

- Storage Tank

- Lube Oil Reservoir

- Any other liquid mediums

Product Features:

- Max power of single heater up to 2000KW-3000KW, maximum voltage 690VAC

- ATEX and IECExapproved. Exd, Exe, IIC Gb, T1-T6

- Zone 1 & 2 applications

- Ingress Protection IP66

- High quality anti-corrosion/high temperature heating element materials:

- Inconel 600

- Incoloy 800/825/840

- Hastelloy, Titanium

- Stainless steel: 304, 321, 310S, 316L

- NiCr 80/20 heating wires, single or double coils.

- Design to ASME code and other International Standards.

- Hair-pin element and sealing to tubesheet by means of Bite-Coupling or Direct Welding. When use with Bite-coupling, individual element can be replaced (offline).

- Over-temperature protection on heating element/flange/terminal box by using PT100, Thermocouple and/or thermostat.

- Flanged connection, ease of installation and maintenance.

- Design for Life in cyclic or continuous operation.